JP / EN

Solution

Laser annealing system

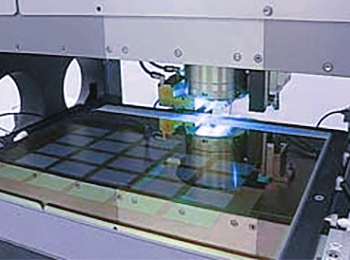

Laser annealing is the modification of the surface layer such as an amorphous Si film formed on a wafer or glass substrate to poly-Si by laser. Annealing system using solid-state laser has little downtime and supports system from 4 inch wafer to G6 substrate.

What is laser annealing?

Laser annealing is the process of quikly melting and cooling the surface layer of an amorphous silicon thin film with a pulse laser to crystallize it to modify it into a polysilicon thin film. In industrial applications, it is used in the process of reforming amorphous silicon into polysilicon in the flat panel display process. ELA using excimer laser was the mainstream, but we moved to solid green laser system with low running cost. However, while the particle size distribution of polysilicon produced by a green laser is sufficient for high resolution LCD TFTs, the particle size and regularity of OLED TFTs have not met the requirements. Therefore, a system (UV-SLA) that uses a UV solid-state laser with a wavelength of 343 nm has been developed for OLED TFT. The UV-SLA process provides a uniform particle size distribution due to multi-shot absorption during scanning.

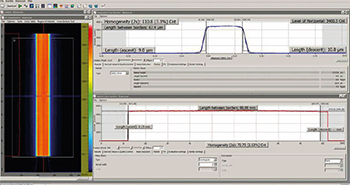

By using UV-SLA, laser annealing with a flat top profile with a large DoF like the profile on the left can be performed. By using this top flat profile, high-speed scanning of 20 mm / s and periodic pattern structure (LIPPS) of poly-Si thin film can be obtained. Since the speed can increase the production tact time, the periodic pattern structure contributes to the speed improvement of the device. UV-SLA enables high throughput and low cost of ownership (40-50% of ELA).

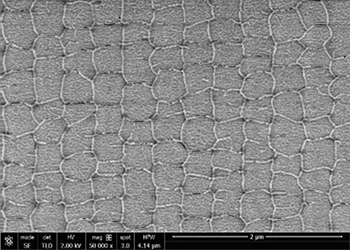

The photo on the left is a SEM image of a thin film after laser annealing in which amorphous silicon is poly-siliconized with a flat top profile by VOLCANO®100UV SLA, a system that uses a UV solid-state laser. Each cell has an irregular shape, but has a regular grain structure as a whole. This period is almost equal to the wavelength of 343 nm of UV solid state laser.

VOLCANO®Line beam laser system

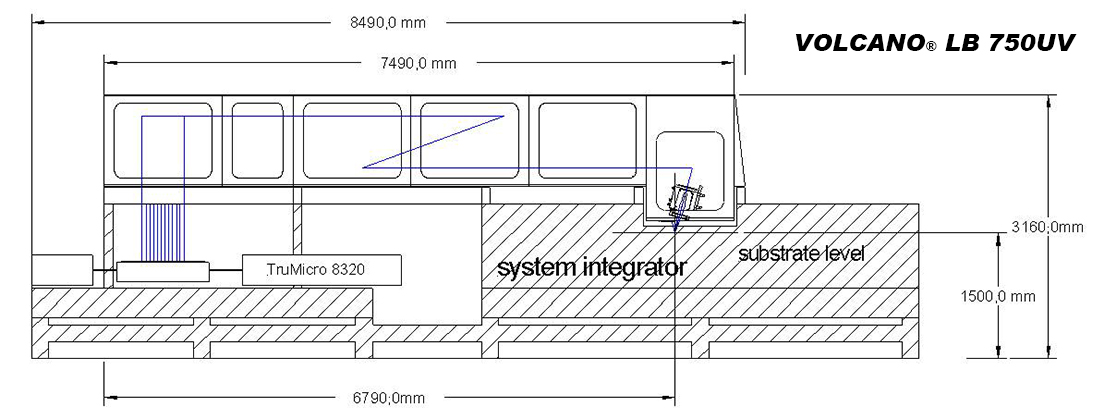

VOLCANO® Line Beam systems can be designed with different line lengths up to 750mm. The use of solid state lasers emitting UV light at 343nm reduces the operating costs and increases the uptime of production tools remarkably, compared to ELA systems using excimer lasers.

The LB systems are based on a rigid aluminum housing structure and the FALCON XXL projection lens gives a working distance of >200mm. A stable and solid system structure is needed to support the line beam optics. Line Beam Optics includes a MBC (Manual Beam Control) camera system which allows to control and adjust position and angle of all laser emitted beams. The FALCON XXL design contains a window which seals the optics from the process chamber and protects against contaminations from the process.

The energy density of 300mJ/cm2 is obtained by using 4 TruMicro 8340 (40mJ specification) with 750mm x 50µm FLATTOP line beam.

The LB systems are based on a rigid aluminum housing structure and the FALCON XXL projection lens gives a working distance of >200mm. A stable and solid system structure is needed to support the line beam optics. Line Beam Optics includes a MBC (Manual Beam Control) camera system which allows to control and adjust position and angle of all laser emitted beams. The FALCON XXL design contains a window which seals the optics from the process chamber and protects against contaminations from the process.

The energy density of 300mJ/cm2 is obtained by using 4 TruMicro 8340 (40mJ specification) with 750mm x 50µm FLATTOP line beam.

| VOLCANO® Line beam laser system specifications | ||||

| Model name | VOLCANO® LB 100UV SLA | VOLCANO® LB 380UV SLA | VOLCANO® LB 750UV SLA | VOLCANO® LB 750G |

| Wavelength | 343nm | 532nm | ||

| Beam length | 100mm(Top hat) | 380mm(Top hat) | 750mm(Top hat) | 750mm (95%) |

| Beam width | 50μm(FLATTOP) | 50μm (FWHM) | ||

| Energy density | >500mJ/cm2 | >300mJ/cm2 | >300mJ/cm2 | 500mJ/cm2 |

| Beam uniformity | 2 Sigma ≤1.0% long axis | 6 Sigma ≤5.0% long axis | ||

| Laser | TruMicro 8320 | TruMicro 8340 | TruMicro 8340 × 4 | Procyon g1600 or g2000 |

| Pulse width | 15 - 20ns | 60 - 100ns | ||