JP / EN

Laser system

Laser cleaning system

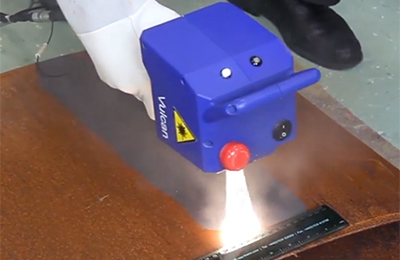

Laser cleaning is a method of peeling rust and paint on the metal surface by pulse laser. It can be easily processed without damaging the substrate. One of them small high output model that can be carried to the site and used and one of them large model .

Laser cleaning system

Vulcan series

Powerlase has successfully combined high average power, high repetition rates, and high intensity pulses with hand held scanners, a combination not previously available. The unique utilisation of these product features introduces laser processing into new and innovative application spaces. The Vulcan family of laser cleaning systems offer rapid paint and coating removal. The fastest of which is a 1.6 kW Q-switched DPSS laser, fibre delivered to a galvanometer based, ergonomic, hand-held, compact scan head.

| Vulcan series specifications | ||

| Model name | Vulcan 500cDatasheet PDF | Vulcan 1600eDatasheet PDF |

| Laser power | 500W | 1600W |

| Pulse energy | 40mJ | 200mJ |

| Pulse width | 70ns - 500ns (Adjustable) | 40ns - 120ns |

Application example of laser cleaning

The high energy pulses of the Vulcan laser cleaning system can reach up to 250mJ thus enabling a detachment or hybrid detachment process that removes paints and coatings at high speed over large spot sizes. The Powerlase Vulcan thus makes the process attractive to industries such as aerospace, energy generation, automotive, marine and others, where paint and coating removal speeds are important.